Belt press for fruits and vegetables

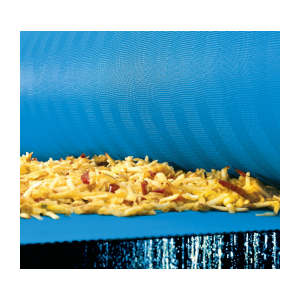

Previously crushed fruits are crushed between a polypropylene belt, which passes through special fruit pressing rollers. After the first squeeze, the pressed material goes through a return shaft to the next (smaller) press roller and is pressed again. The belt is automatically tensioned by pneumatic actuators.

The material from which the juice is squeezed is scraped off the belt by the end scraper, thus being removed from the press. The squeezed juice passes through a sieve belt and goes to the juice collection tank from which it is pumped out. During this process, the belt is washed with a jet of water under pressure.

Efficiency kg/h, l/h

Up to 800 kg/h, 500 l/h

Installation power

0.8 kW

Juice pump

YES

Juice tank sieve

YES

Belt width (mm)

500 mm

Dimensions L x W x H (mm)

2200x1230x1400

Automatic scraper lifting system

OPTION

Belt washing brush (with drive)

NO

Advantages of the single belt press

- Made of stainless steel

- Smooth speed control and compression pressure control

- Low maintenance costs

- Easy to operate

- Automatic belt feed adjustment

- Completely enclosed stainless steel bearings

- Easy to clean

- High-pressure belt cleaning system

Intended for fruit and vegetables The machine is made of very durable materials and components, which means it can be used for a long time without any signs of wear and